Ferometal Prerada d.o.o. operates one of the most advanced machine parks

for producing highly demanding metal components. From 5-axis machining centers

and high-speed mills to advanced Y-axis lathes and industrial 3D measuring systems,

every machine plays a crucial role in delivering precise, repeatable,

and flawlessly finished products.

Below is a complete presentation of our machine park, demonstrating the strength,

capacity, and technological advantage of our production capabilities—

enabling the creation of even the most demanding components.

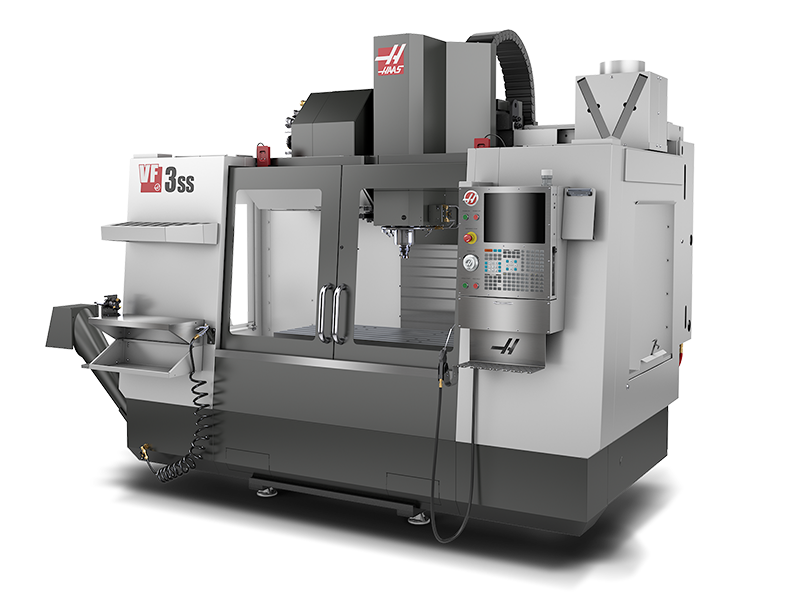

Fast, precise, and stable machining of demanding components— delivering perfect surface quality and repeatability for both series and prototype production.

Increased working area and faster cycle times enable the production of technically complex parts with excellent repeatability.

Number of machines: 2

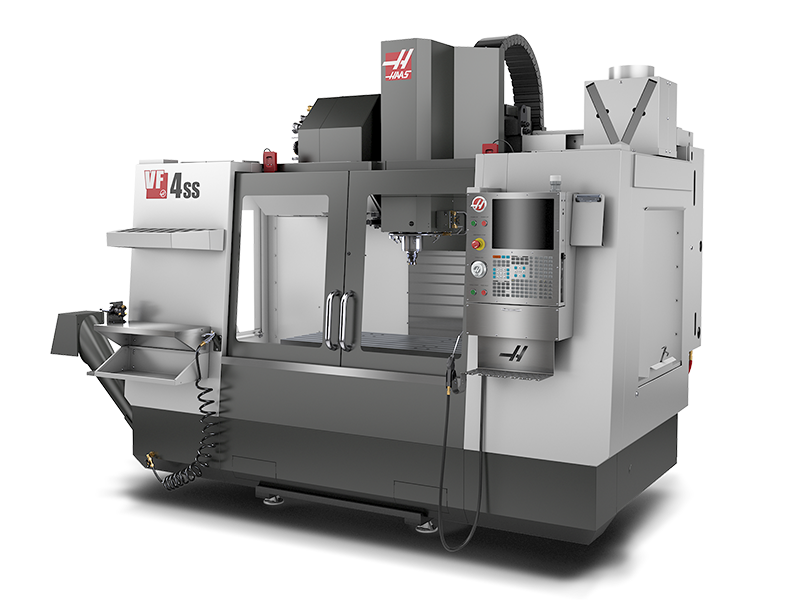

The optimal balance of size and productivity—perfect for machining medium and larger components with minimal cycle times.

Number of machines: 3

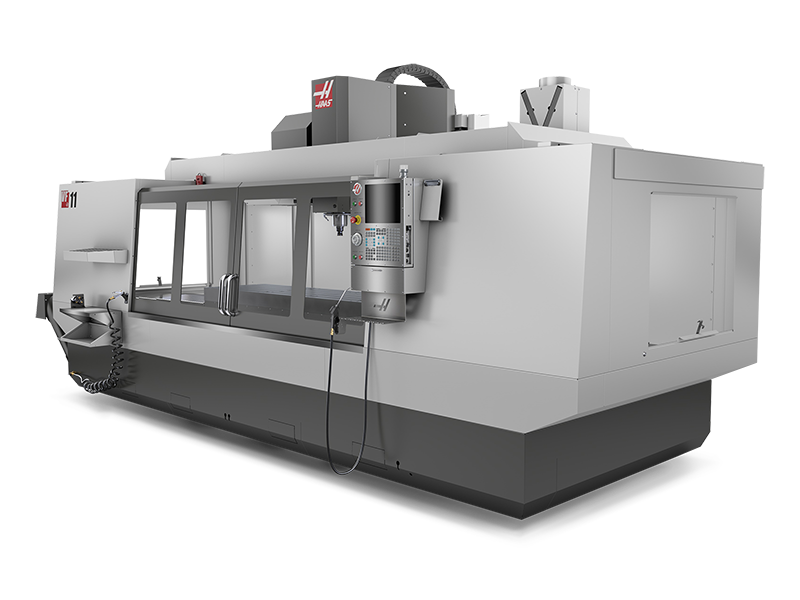

Ideal for massive and long components requiring high stability, rigidity, and excellent surface finish.

Number of machines: 3

Premium 5-axis machining—perfectly precise geometry completed in a single setup without repositioning.

Number of machines: 2

Engineered for machining extremely large structural components—delivering stability, power, and perfect geometry even on the longest parts.

Turning and milling in a single setup—ideal for complex, multi-operation parts that require Y-axis flexibility.

Number of machines: 2

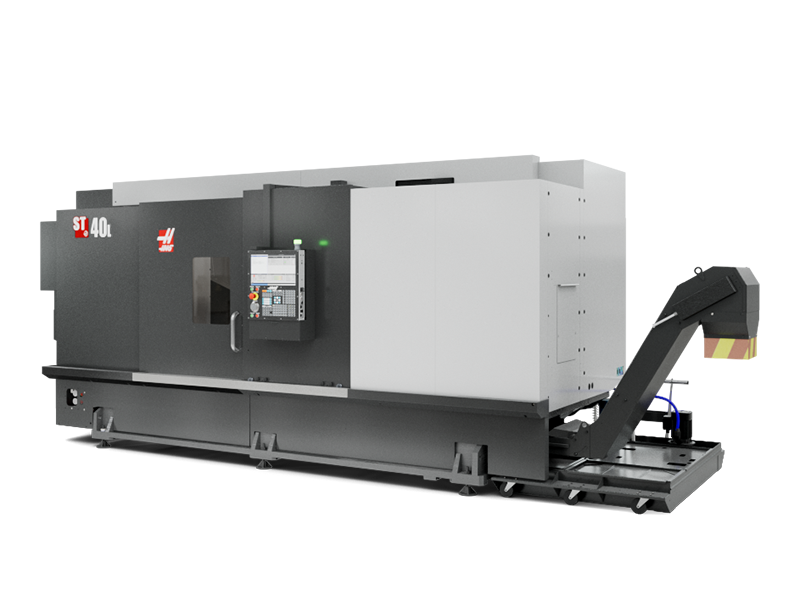

Built for heavy-duty machining of larger diameters. The Y-axis provides precise side and combined machining in a single setup.

Compact and precise machine for fast and stable production of small and medium cylindrical components.

Advanced Y-axis capability enables machining of complex shapes— ideal for geometrically demanding parts.

Perfect for small, high-precision components, with minimal vibration and exceptional repeatability at tight tolerances.

Specialized for long cylindrical components—offering exceptional stability and rigidity during heavy and extended machining operations.

Number of machines: 2

Optimal for machining large diameters and massive cylindrical components— powerful spindle and stable construction for heavy cutting conditions.

Industrial 3D measuring system with exceptional accuracy— ensuring complete quality control of all manufactured components.

Mobile 3D measuring system—enabling fast, flexible, and highly precise quality control directly at the production site.